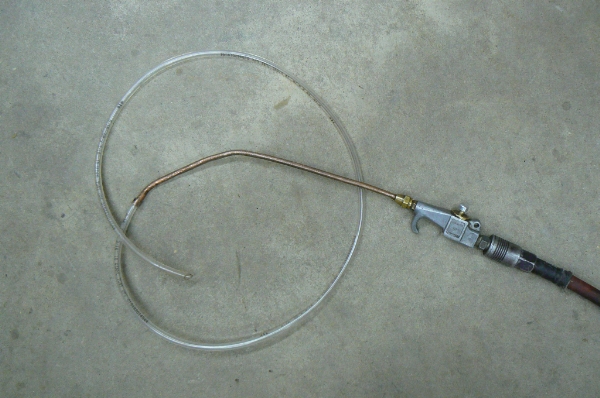

| I put long piece of clear tubing on my air gun and would feed it into whatever hole I could and spray the interior of the housing with high pressure air while slowly pulling out the hose. The soft vinyl tubing would whip wildly when air was applied and I hoped that it would find and move the nut. |

| After 2 nights of turning the engine a couple of degrees and repeating the spray of air the very edge of the nut showed up along the edge of the opening between the block and the flywheel. I was able to work it out with a dental pick. What a relief! You can just see the edge of the nut in the circle in the picture. |

| The rest of the repairs were pretty straightforward and went smoothly. I replaced some of the lifters that felt weak with some good used ones (Ebay) and I completely drained the fuel tank and got a ton of crap out of it. I replaced the fuel filter, air filter, cap and rotor and loads of other parts. It's always a thrill to turn the key and hear it run again and it ran better and a lot quieter than before. BUT, once it got up to pressure the radiator had a slight leak so it had to be replaced. I had a 4 wheel alignment done and all the suspension components checked and tires balanced. It passed state inspection and is now on the road. |

| Quite a contrast from the before pictures on page 1 |

| I've spent most of the summer enjoying the Porsche but with the addition of the wifes SLK230 I now had too many vehicles and something had to go. I was ready to sell the 944 when "BANG" the transmission went out. Looks like I'll be adding another page to this story |

| UPDATE ! |